Yas provides a wide variety of ACR/DHP graded copper tubes and fittings used for Air-conditioning, Refrigeration, Gas lines and other heating and cooling industrial purposes.

These are supplied from best of the manufacturers according to the client’s specifications meeting international Standards including ASTM, JIS, BS-EN and IS Codes.

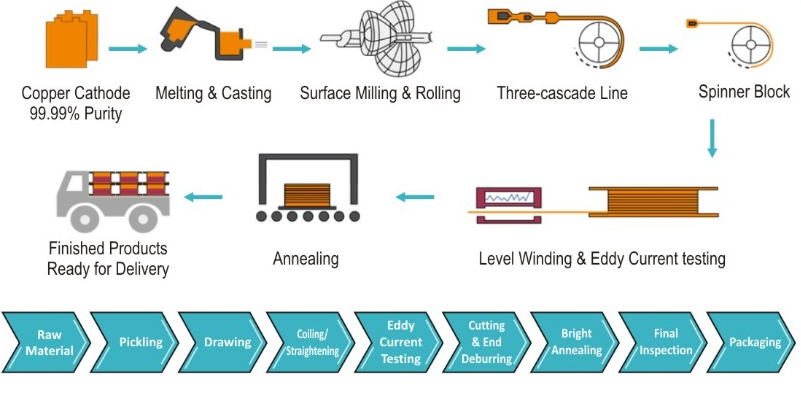

These Manufacturers are selected with experience of our founder who is self-experienced in Manufacturing Copper tubes. They manufacture the tubes with proper Technical standards and Testing Equipment’s.

Here we focus on the quality weather used for residential or commercial purposes and hence are proud to supply to a wide range of refrigeration, air conditioning, LPG line etc. needs .

To have a look at the catalog checkout our catalogs page or click on the following link to visit the page.(https://refmart.in/e-catalogues/)